Our state-of-the-art research facility is located in the School of Engineering at the University of Minho. Equipped with the latest technologies and materials, our facility is designed to support innovative research and development of cutting-edge textile fibers.

Our team of experts has access to a wide range of equipment, including advanced testing and analysis tools, 3D printers, and specialized machinery for fiber processing and production. We are committed to providing a collaborative and dynamic work environment that fosters creativity and innovation.

AZURÉM, BUILDING 3

Functional Finishes Laboratory II

Azurém, Building 3, 1.02

In the Functional Finishes Laboratory II, compounds, nanomaterials, and innovative fibers are prepared and characterized. This laboratory enables the execution of the most common processes in the textile industry for dyeing or functionalizing: exhaustion and impregnation. These approaches facilitate the functionalization and dyeing of conventional textiles and advanced textiles, such as nanotextiles, with compounds and nanocompounds featuring improved properties and activities to create advanced multifunctional textiles.

EQUIPMENT:

– Dyeing equipment (Ibelus)

– Padding mangle

– Washing fastness evaluation equipment

(Fastness Test)

– Rubbing fastness evaluation equipment

(Crockmeter)

– Wet-spinning systems

– Pressure dyeing equipment (20 PSI)

– Pressure filtration system

– pH meter for liquids and solids

– Precision scale

– Regular scale

– Magnetic stirrer with agitation

– Heating/cooling bath – Stirred bath

– Oven – Biological oxygen demand meters

– Vacuum pump – Ultrasonic bath

– Climatic chamber – Slicer

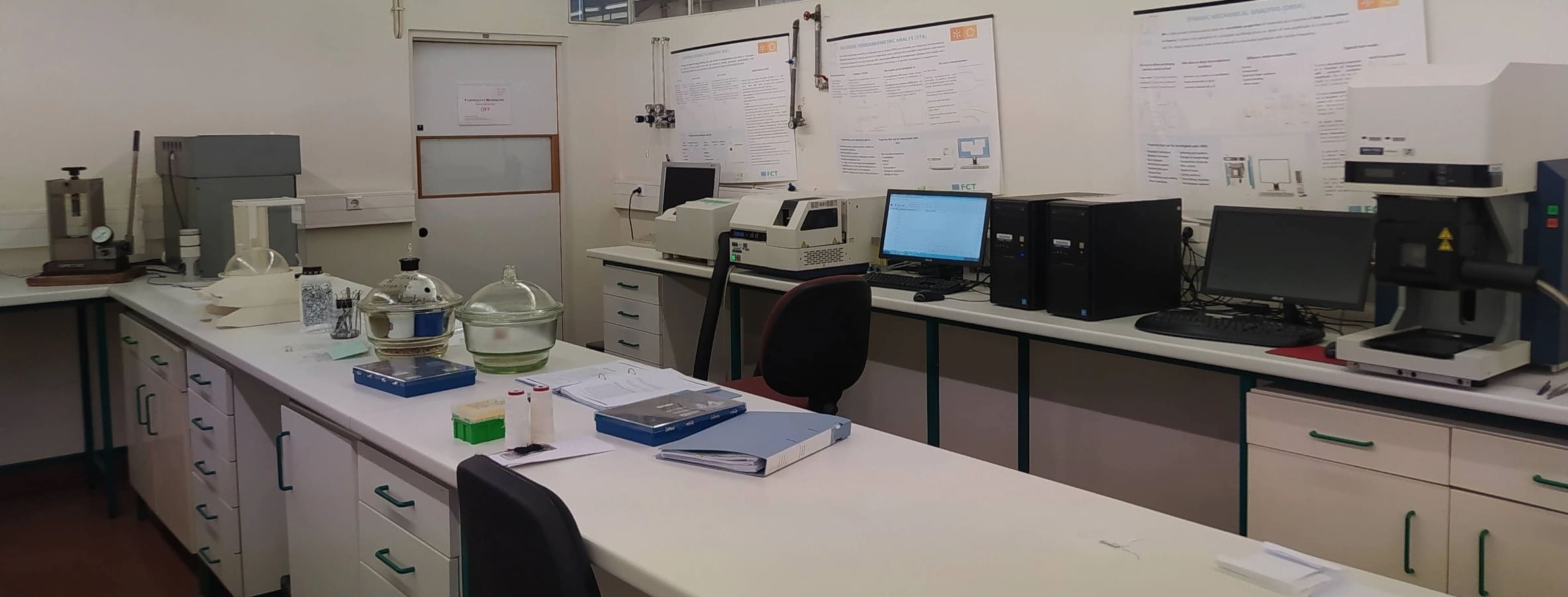

Advanced Textile Materials Analysis Laboratory

Azurém, Building 3, 1.03

In the Advanced Textile Materials Analysis Laboratory, multiple characterization tests of textile materials are conducted, including: resistance to ultraviolet rays and weathering, wettability, chemical and physical properties, and conductivity. In this laboratory, it is possible to characterize the UV protection index, quantify color and its variation. The size and architecture of fibers can be verified with different levels of microscopic magnification.

EQUIPMENT:

– Potentiostat

– Light chamber

– Fourier Transform Infrared Spectroscopy (FTIR) with Attenuated Total Reflectance (ATR) KBr pellet and liquid samples

– Ultraviolet Radiation Aging Chamber (UV)

– Differential Scanning Calorimetry (DSC)

– Thermogravimetric Analysis (TGA)

– Dynamic Mechanical Analysis (DMA)

– Magnifying glass

– Fluorescence microscope

– Bright-field microscope

– Press – Precision scale

– Spectrophotometer for absorbance, reflectance, and fluorescence of solids and liquids

– Goniometer – Rotavapor

– Fume hood

– Ultra-pure water system

– Scanning Electron Microscopy (SEM)

Functional Finishes Laboratory I

Azurém, Building 3, 1.16

In Functional Finishes Laboratory I, textiles are prepared and functionalized, covering conventional textiles, nonwovens obtained by electrospinning, and various structures obtained through wet spinning. Equipped with state-of-the-art hot press, it is possible to consolidate all types of textiles, enabling the creation of multifunctional textiles. This laboratory also serves as support for the Microbiology Laboratory.

EQUIPMENT:

– Press

– Centrifuge

– Orbital shaker

– Oven – Autoclave

– pH/oxygen/conductivity meter

– Microwave

– Scale

– Precision scale

– Magnetic stirrer with heating

– Autoclave

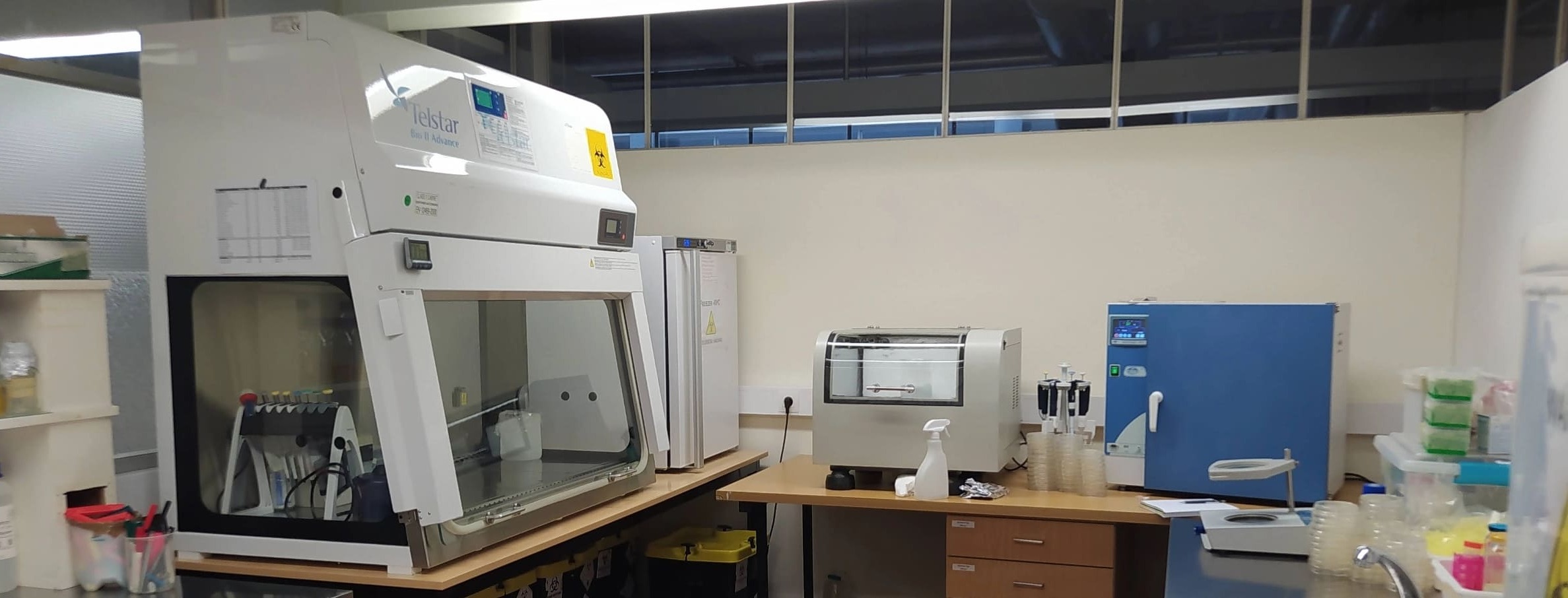

Microbiology Laboratory

Azurém, Building 3, 1.16.1

In the Microbiology Laboratory, the antimicrobial properties of innovative yarns and textiles are verified and quantified. This Biosafety Level 2 laboratory evaluates antibacterial, antifungal, and antiviral properties. Additionally, this laboratory handles microorganisms capable of generating nano-nonwovens and dyes that can replace currently used chemical dyes. The laboratory’s collection includes bacteria, fungi, and bacteriophage.

EQUIPMENT:

– Incubator

– Orbital shaking incubator

– -80°C freezer – Class II Biological Safety Cabinet

– Colony counter and magnifying glass

– Vortex mixer

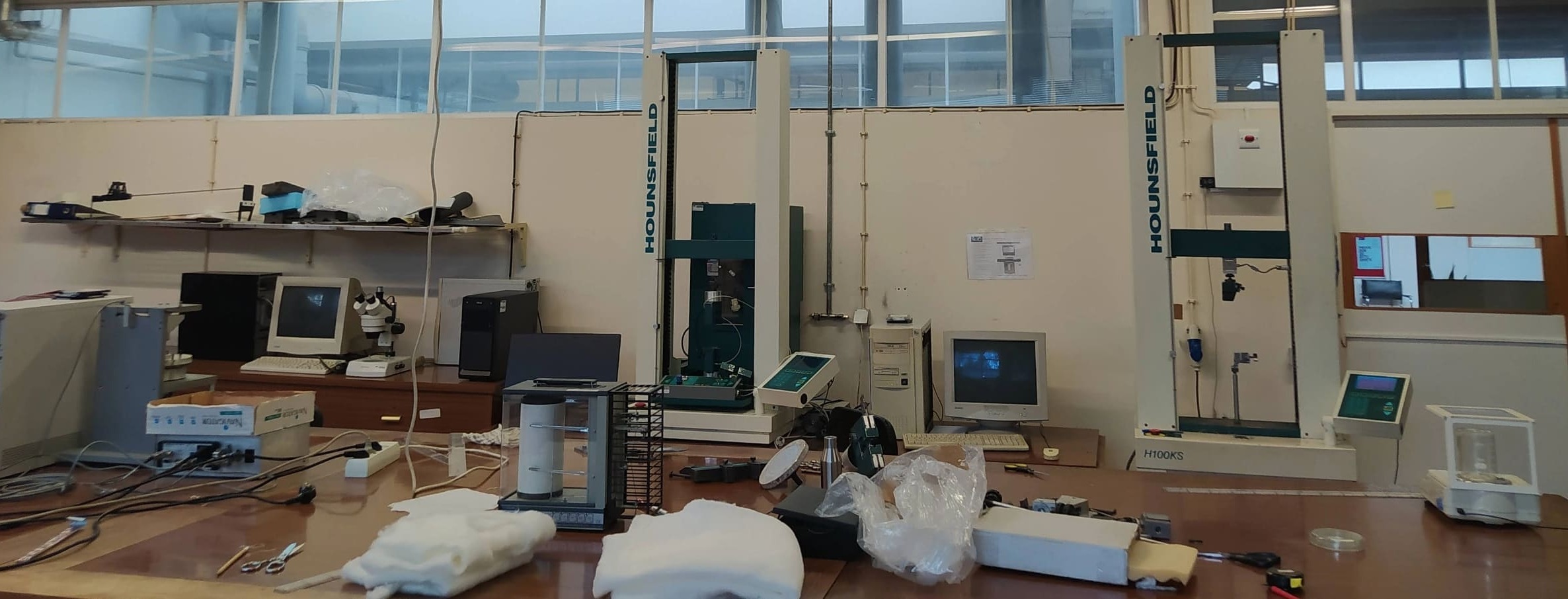

Textile Physics Research Laboratory

Azurém, Building 3, 1.17

The Textile Physics Laboratory is dedicated to the physical characterization of fibrous materials, from yarns to textile structures, including their behavior regarding: tensile strength, compression, puncture resistance, three-point bending, air permeability, and impact resistance. Additionally, conductive, thermophysiological, and thermal insulation properties can also be quantified.

EQUIPMENT:

– Dynamometer with and without climatic chamber

– Climatic chamber

– Power supply and conductivimeter

– Grab tester

– Tog meter

– Impact resistance tester

– Cantilever

– Air permeability tester

– FricTorque tester

Research Chemistry Laboratory

Azurém, Building 3, 1.19

In the Research Chemistry Laboratory, active compounds are prepared and characterized to provide properties and activities that conventional textiles do not possess. Among them are natural plant extracts that have antimicrobial activity while promoting cell proliferation, making them excellent compounds for application in innovative yarns produced through wet spinning.

EQUIPMENT:

– Wet spinning systems

– Kjeldahl – Oven

– Muffle furnace

– Vacuum pump

– Ultrasonic bath

– Fume hood

– Precision scale

– Magnetic stirrer

– Distillation apparatus

Textile Processes Laboratory I

Azurém, Building 3, 0.32 and 0.33

In Textile Processes Laboratory I, it is possible to produce the three major types of textiles: knits, woven fabrics, and nonwovens. In this laboratory, it is possible to produce warp and weft knits on both flatbed and circular looms, including seamless knits. Woven fabrics, including Jacquard fabrics, and nonwovens by needle punching can also be produced. Additionally, it is possible to decorticate and grind plant material to produce innovative natural fibers.

EQUIPMENT:

– Computerized flat knitting machine

– Manual flat knitting machine

– Cylinder circular knitting machine

– Cylinder and dial circular knitting machine

– Seamless circular knitting machine

– Interlock circular knitting machine

– Warp knitting machine

– Raschel knitting machine

– Jacquard loom – Braiding machine

– Decorticator

– Disc mill